IndPrint

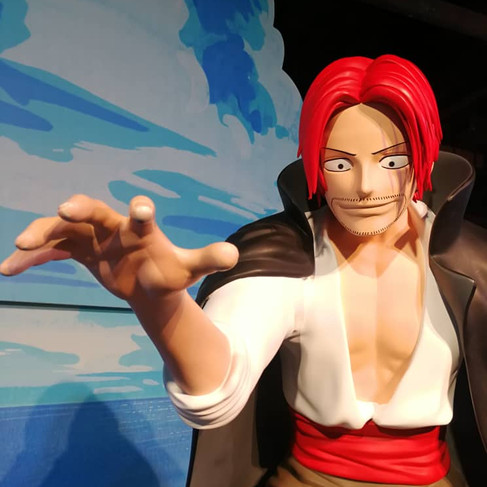

Manga and comic series One Piece has marked its 20th anniversary with an exhibition featuring 24 huge 3D printed replicas of its leading characters which have been produced on a Massivit 3D printer.

Visiting fans have been able to interact with all the characters that have ever appeared in print or animation during a two month show in Taipei, Taiwan.

One Piece, written and illustrated by Eiichiro Oda – an artist renowned for changing the history of manga – has recorded the highest initial print run of any book in Japan. There are more than 450 million in circulation worldwide. It also set a Guinness World Record for ‘the most copies published for the same comic book series by a single author’. One Piece has been adapted into a festival film, an anime series, thirteen animated feature films, one original video animation, thirteen television specials and developed into a media franchise.

SID Installation Art was commissioned by event organiser Remake Works and One Piece Mugiwara Store Taiwan, to bring these immensely popular characters to life using its Massivit 3D 1800 Pro 3D printer. Fans at the event have revelled over the characters, interacting with the 1.8 metre to 5 metre tall models and sharing augmented reality clips of themselves on social media via the event app that films them in customized scenes.

Previously, SID Installation Art worked predominantly with Styrofoam and fiberglass to produce gaming and manga related props. However, the company found this process to be very tedious, requiring a lot of skilled labour and time. 3D printing has proven to be faster, with more creative possibilities, and capable of executing highly complex jobs in dramatically less time. For this reason, the business chose to incorporate large format 3D printing production capabilities into its offering with the adoption of a Massivit 1800 Pro 3D ‘rinter. As a result, SID Installation Art has now established key relationships with events, exhibition and gaming producers, interior designers, and architects.

Hung Jui Chia, COO of SID Installation Art, said: ‘3D printing has proven to be a real game changer for us in terms of our overall turnaround time, the accuracy we are able to achieve, the production size, and new possibilities for creative vision. Although our team is nationally recognised for its expertise in hand sculpting, the benefits of digital, large format 3D printing are clear. We have dramatically reduced our lead time on projects due to the ability to share the initial digital 3D model and iterations with clients in order to finalise design specifications quickly and with the confidence that the 3D model accurately represents the final output. Moreover, the Massivit 3D printer enables us to produce models in half the time it would have taken with our traditional manufacturing processes, largely because we no longer need to create a preliminary mould which is the bottle neck. This means we can accept a greater volume of jobs – our Massivit 3D printer is in use 18 hours per day.’